Valve type bag for powder packing

Product Details:

- Product Type Valve Type Bag

- Material High Strength Paper, Multi-layer Kraft, or Polypropylene

- Bag Type Powder Packing Bag

- Style Block Bottom or Side Gusset

- Sealing & Handle Valve Seal, No Handle

- Surface Handling Printable Surface, Optional Laminated

- Industrial Use Cement, Chemicals, Minerals, Food Powder, Construction Materials

- Click to View more

Valve type bag for powder packing Price And Quantity

- 40 INR/Piece

- 5000 Piece

Valve type bag for powder packing Product Specifications

- Powder Packing Bag

- White, Brown, or Custom Printed

- Automatic Valve Closure

- Valve Type Bag

- 320 mm to 500 mm

- Cement, Chemicals, Minerals, Food Powder, Construction Materials

- High Strength Paper, Multi-layer Kraft, or Polypropylene

- Customizable, Common Sizes from 10kg to 50kg capacity

- Block Bottom or Side Gusset

- Flexographic or Rotogravure

- Valve Seal, No Handle

- Printable Surface, Optional Laminated

- 430 mm to 1200 mm

- Not Included

Valve type bag for powder packing Trade Information

- 10000 Piece Per Month

- 15-20 Days

- Western Europe, Australia, Eastern Europe, Middle East, Central America, South America, Asia, North America, Africa

- Himachal Pradesh, Sikkim, Tripura, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Nagaland, , South India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Chandigarh, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Bihar, Punjab, Pondicherry, Rajasthan, Tamil Nadu, Telangana, West Bengal, Gujarat, Kerala, Central India, Odisha, Chhattisgarh, Uttar Pradesh, All India

Product Description

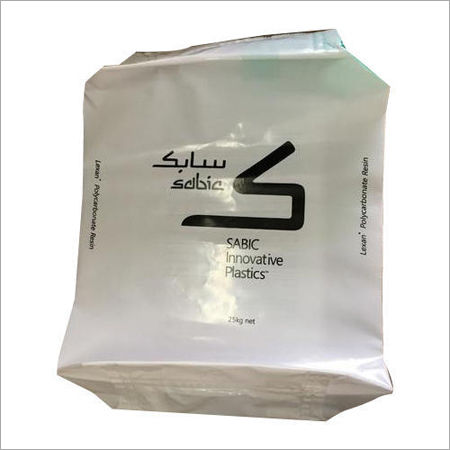

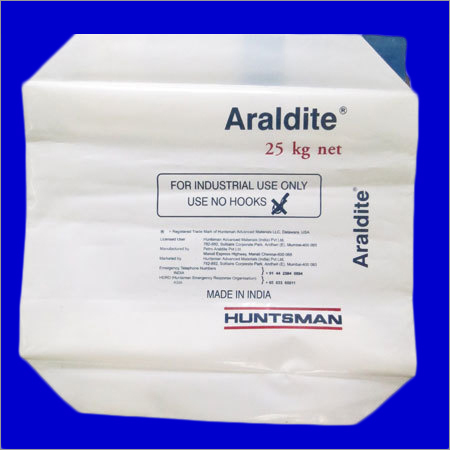

Valve type bag for powder packing

Buy from us valve type bag for powder packing. The material in the form of powder is filled in such kind of bag via a tube that is inserted into a small opening (also known as valve) located on the top corner of the bag. Following filling, the opening is sealed to secure the bag. A benefit of using such type of packaging bag in the pack aging process is that it does not require the use of machines, like sewing machine or bag sealer to close. LDPE, LLDPE are the material which are mainly utilized in the production of such bag meant for industrial and retail use.

Valve type bag for powder packing

Product Details

Packing Type | Packet |

Brand | Ashirvad Enterprise |

Design Type | Customized |

Pattern | Plain |

Virgin Quality | 100% Virgin |

Sample Required | Yes |

Material | LDPE, LLDPE |

Usages | Industrial |

Versatile Layer Construction

Choose from single to multi-ply (2-5 layers) construction to match your product's protection and handling needs. Our bags efficiently pack dry powders, granules, and minerals, ensuring safe and secure transportation or storage in various industrial sectors.

Innovative Valve System

With standard or extended valve designs and automatic closure technology, our bags offer quick and clean filling processes. Multiple sealing options, such as self-sealing, heat-sealed, or glued closures, enhance powder containment while eliminating spillage during handling.

Customizable & Eco-Friendly Packaging

Tailor your powder packing bags with custom logos, product details, or brand colors. We offer flat packed or bundled delivery, optional micro-perforation for venting, and UV protection. Made with recyclable materials, our bags support your sustainability goals.

FAQ's of Valve type bag for powder packing:

Q: How does the valve mechanism in your powder packing bags work?

A: The valve mechanism features either a standard or extended valve, allowing efficient filling of dry powders and bulk solids. After filling, the valve automatically seals (or can be heat sealed/glued), ensuring the contents remain secure and reducing dust or spillage.Q: What is the benefit of multi-ply layer construction in these bags?

A: Multi-ply (2-5 layers) construction enhances bag strength, puncture resistance, and moisture protection. This design is particularly beneficial for heavy-duty or hygroscopic powders, providing durability and integrity during transport and storage.Q: Where can these bags be used and for what types of materials?

A: Valve type bags are ideal for packing cement, chemicals, minerals, food powders, and other dry bulk solids. They are designed to meet industrial requirements in sectors such as construction material supply, mining, and food processing.Q: What options are available for moisture and UV protection?

A: We offer bags with moisture barriers through PE coating or lamination and optional UV-treated materials. These features help shield contents from environmental factors, extending shelf life and maintaining product quality during outdoor storage.Q: Can the packaging be customized regarding size, color, and print?

A: Yes, sizes range from 10 kg to 50 kg capacity, with widths from 320 mm to 500 mm and lengths from 430 mm to 1200 mm. Bags can be made in white, brown, or custom colors and printed using flexographic or rotogravure methods for personalized branding.Q: What is the process for ordering, and what is the minimum order quantity?

A: Ordering involves selecting desired specifications (layer count, valve type, size, print, etc.). Minimum order quantity is set as per manufacturer requirements-contact us to discuss your application and obtain a tailored quote.Q: Are these bags environmentally friendly and recyclable?

A: Yes, crafted from eco-friendly materials such as high-strength paper and polypropylene, our bags are recyclable and support sustainable packaging initiatives in line with modern environmental standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+