Heavy Duty Valve Bag

Product Details:

- Product Type Heavy Duty Valve Bag

- Material Woven Polypropylene (PP)

- Bag Type Valve Bag

- Style Block Bottom

- Sealing & Handle Ultrasonically Sealed Valve

- Surface Handling Flexographic Printed

- Industrial Use Cement, Chemicals, Food grains, Fertilizer, and Building Materials

- Click to View more

Heavy Duty Valve Bag Price And Quantity

- 40 INR/Piece

- 5000 Piece

Heavy Duty Valve Bag Product Specifications

- White with Custom Print

- Block Bottom

- Valve Bag

- Woven Polypropylene (PP)

- Flexographic Printed

- Cement, Chemicals, Food grains, Fertilizer, and Building Materials

- 90 cm

- Ultrasonically Sealed Valve

- Laminated Woven Technology

- 50kg Standard (Custom Sizes Available)

- Heavy Duty Valve Bag

- Multi-Colour Flexo Printing

- 50 cm

Heavy Duty Valve Bag Trade Information

- 10000 Piece Per Month

- 15-20 Days

Product Description

Heavy Duty Valve Bag

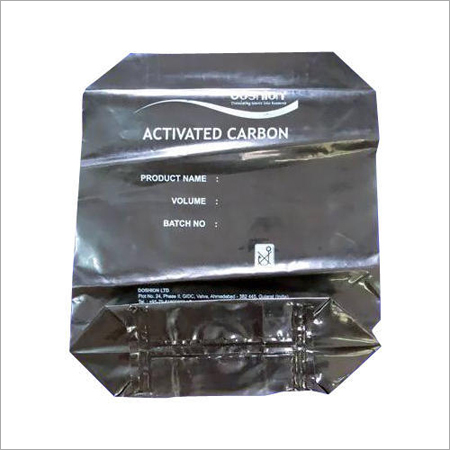

A heavy duty valve bag is closed across the top, but has an opening on its upper side corner. The dry product, mainly in the form of powder, flakes and granules, is filled in the bag over a fill tube. The bag is removed from the tube after it has been filled, and the valve is shut. This plastic, black bag can be printed with white text. As with this bag, you can see the product name is written in capital letters and under that information of the product, such as product name, volume and batch number are added.

Prices may vary as per the raw material price, size and thickness of the bags.

Product details

| Storage Capacity | 25 Kgs |

| Pattern | Printed |

| Design Type | Customized |

| Material | LDPE, LLDPE |

| Color | Any |

| Usage | Industrial |

| Virgin Quality | 100% Virgin |

| Sample Required | Yes |

| Brand | Ashirvad Enterprise |

Engineered for Optimal Strength and Protection

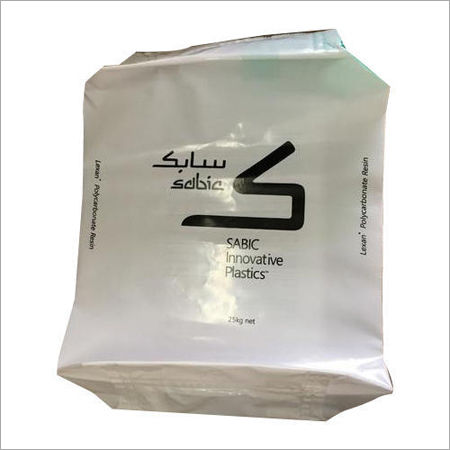

Designed for heavy-duty industrial use, these valve bags offer high tear resistance and block-bottom stability, making them perfect for stacking and transport. Laminated to ensure a complete moisture barrier, each bag is ultrasonically sealed to maintain contents integrity and extend shelf-life, even in tough environments.

Versatile Applications and Customization

Suited for packaging cement, chemicals, fertilizers, food grains, and building materials, our valve bags can be flexographically printed in up to eight vibrant colors. Options for custom sizes, colors, and optional UV protection allow you to tailor each bag to your specific operational and branding requirements.

Efficient Packing and Sustainable Handling

With a self-closing valve mouth and single-use recyclable construction, the bags enable quick, clean, and secure filling. Their moisture-proof and durable build reduces wastage, enhances product safety, and supports eco-friendly disposal after use.

FAQs of Heavy Duty Valve Bag:

Q: How do the self-closing valve mouths enhance filling efficiency?

A: The self-closing valve mouth allows for rapid, mess-free filling. Once the material is loaded, the valve automatically seals, ensuring the contents remain secure and reducing the need for additional sealing steps during packaging.Q: What advantages do block-bottom valve bags offer in storage and transport?

A: The block-bottom design maintains a stable, rigid shape, allowing the bags to stack securely without collapsing. This improves storage efficiency and safety in both warehouse and transport environments.Q: When should UV protection be considered with these bags?

A: Opt for UV protection if the bags will be exposed to sunlight for extended periods during storage or transportation. UV additives help prevent degradation of the polypropylene material, prolonging the bags durability outdoors.Q: Where are these heavy duty valve bags commonly used?

A: They are widely employed in industries packing cement, fertilizers, chemicals, food grains, and building materials. The bags robustness and moisture-proof construction make them suitable for demanding industrial and export applications.Q: What is the typical process for ordering custom printed valve bags?

A: Share your size, color, and printing specificationssuch as logos or product details. We use high-resolution flexographic printing (up to 8 colors) to meet your branding needs and can supply bags with optional UV protection based on your usage requirements.Q: How does the laminated woven polypropylene construction benefit product storage?

A: Laminated woven PP offers an excellent moisture barrier and superior tensile strength. This keeps powdered and granular products dry, preserves their shelf-life, and protects contents from environmental factors during storage and shipping.Q: Can these valve bags be reused or recycled after initial use?

A: Although designed primarily for single-use, the bags are fully recyclable. Their construction permits straightforward disposal in recycling streams, supporting sustainable practices without compromising packaging performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+